On May 27, at the 11th China International New Energy Vehicle Forum, Huawei's DriveONE ePowertrain wins "Key Technology Breakthrough Award for ePowertrain "!

Huawei DriveONE ePowertrain Wins the Key Technology Breakthrough Award for ePowertrain

Huawei DriveONE ePowertrain Wins the Key Technology Breakthrough Award for ePowertrain

1. The industry's exclusive high-voltage asynchronous ePowertrain system, creating a high-voltage four-wheel drive with the best energy efficiency

Current four-wheel drive systems for electric vehicles (EVs) mostly use low-voltage architecture, which does not support SuperCharge. Limited by the maximum power of four-wheel drive, the acceleration performance is not ideal and the energy efficiency of ePowertrain is not optimal under different working conditions. Rising to this challenge, Huawei launched the "AI Flash Charging" power domain full-stack high-voltage solution at Auto Shanghai 2021. The 220 kW asynchronous front-drive and 270 kW synchronous rear-drive is the only high-voltage electric four-wheel-drive solution in the industry, bringing ultra-high horsepower and flash charging to EVs. The 800 V high-voltage architecture allows the vehicle to complete 30% to 80% SOC charging within 15 minutes, the time you would need to drink a cup of coffee. Equipped with this high-voltage four-wheel drive solution, the ARCFOX αS HI version by BAIC can accelerate from 0 to 100 km/h in 3.5 seconds, which is comparable to the power performance of super cars. Compared with the industry's synchronous on the front and asynchronous on the rear solution, Huawei's high-voltage four-wheel drive solution has an NEDC of more than 3.5%, increasing the cruising range by 5%.

DriveONE 3-in-1 ePowertrain, creating the industry's exclusive "synchronous on the front and asynchronous on the rear " high-voltage four-wheel drive solution

DriveONE 3-in-1 ePowertrain, creating the industry's exclusive "synchronous on the front and asynchronous on the rear " high-voltage four-wheel drive solution

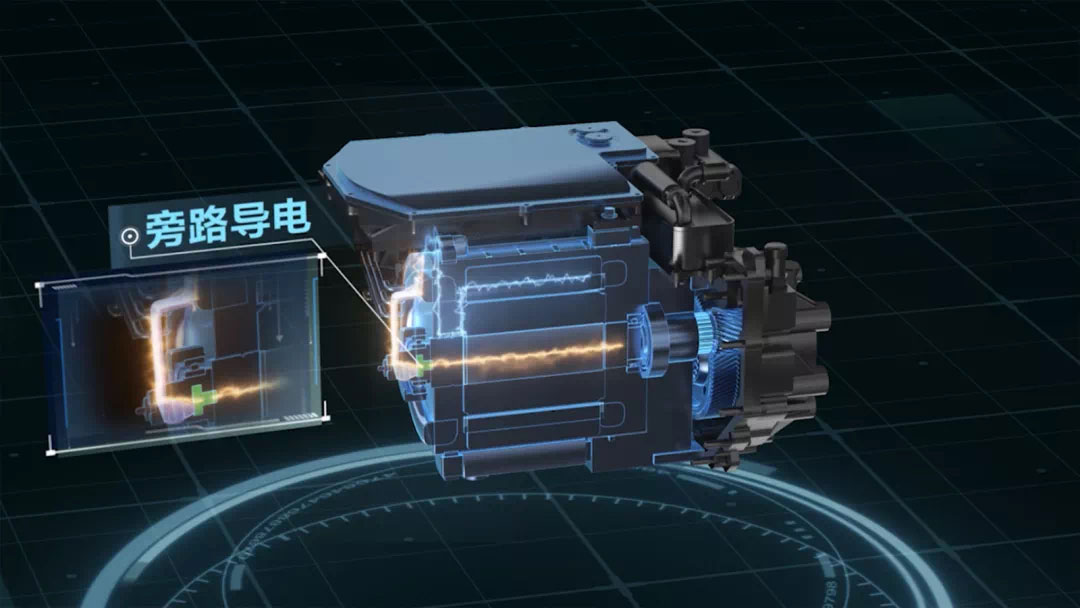

2. "Franklin" patented deflection technology, effectively reducing the risk of electrical corrosion of bearings

Consumers are attracted by the power and driving comfort of EVs. Electrical corrosion of motor bearings is caused by the breakdown of the bearing oil film by shaft voltage, which is prone to problems such as jitter and abnormal noise after running for a long time. To overcome this problem, the Huawei DriveONE ePowertrain adopts the "Franklin" patented deflection solution, adding an additional bypass conductive circuit to release the shaft voltage and shaft current and effectively reducing the risk of breakdown. Huawei also uses conductive grease with patented ratio, which has excellent electrical conductivity, compatibility, and temperature and pressure resistance, which further prevent electrical corrosion of bearings.

Using "Franklin" patented deflection technology to prevent electric corrosion of bearings

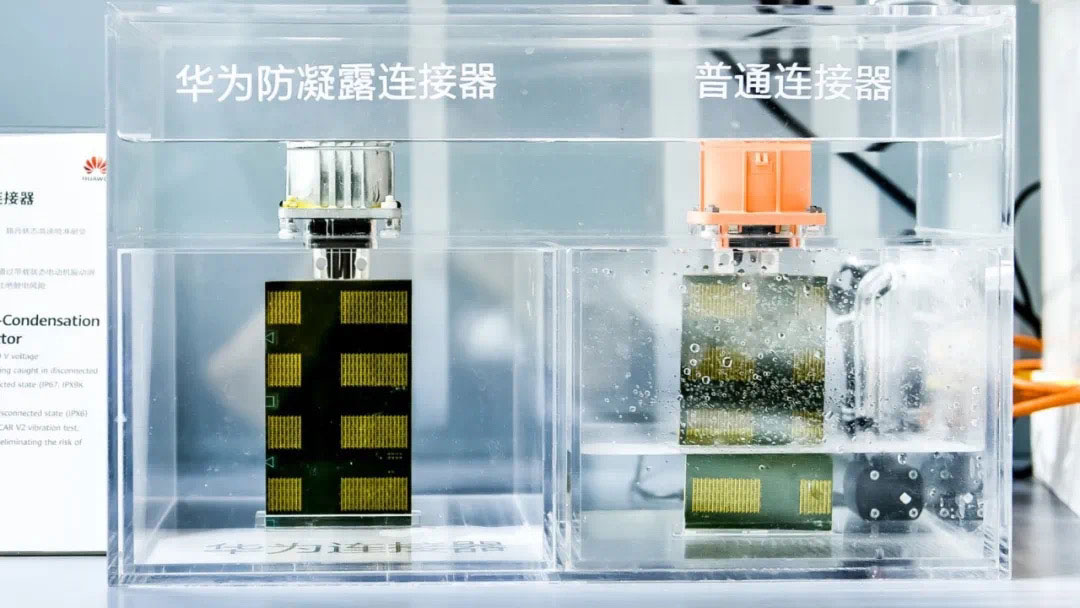

3. Patented anti-condensation high voltage connector to prevent potential safety hazards

The temperature difference inside and outside the electrical equipment will cause condensation at the connector and is likely to result in accidents. The Huawei-developed anti-condensation connector uses the mature structure of the existing connector and adds special sealing parts (patented improvements) to form a unilateral sealed structure, which isolates the equipment cavity and the connector cavity from the "road" end and effectively prevents connector condensation. Through individual tests such as electrical, structural machinery, and reliability tests, and complete machine tests such as conventional, mechanical, and climatic tests, the quality of the connector is fully guaranteed.

Huawei anti-condensation connectors effectively prevent condensation on high-voltage connectors

Huawei DriveONE will use "digital technology + digital platform" to overcome key technology challenges in the EV power domain, and provide the industry with innovative, AI- and cloud-based power domain solutions that feature high convergence, simplicity, safety and reliability, excellent experience. Huawei will help automakers build better cars to provide better electrified transportation to users around the world.

Search

Search

Search

Search